Did you know that without transformers, our modern electrical systems would be virtually impossible? These remarkable devices play a crucial role in ensuring a smooth and efficient flow of electricity from power plants to our homes, offices, and industries.

But have you ever wondered about the intricate inner workings of these silent powerhouses? These powerful electrical components play a crucial role in our daily lives, and understanding each transformer’s parts can help you appreciate their remarkable capabilities. From coils and cores to windings and insulating materials, let’s take a closer look at the heart of these electrical marvels and explore how they shape the world of electricity.

Understanding Transformers

A transformer is a fundamental electrical device that efficiently transfers electrical energy from one circuit to another through electromagnetic induction. Its primary role is to alter the voltage level of alternating current (AC) electricity at the input and output terminals while maintaining the frequency of the electrical signal.

Originating from the work of pioneers like Michael Faraday, practical transformer designs emerged in the late 1800s. These devices play a crucial role in electricity distribution by converting voltages, enabling efficient transmission, ensuring load balance, enhancing safety, and regulating voltage. Their significance lies in facilitating the reliable and safe delivery of electrical power to various users.

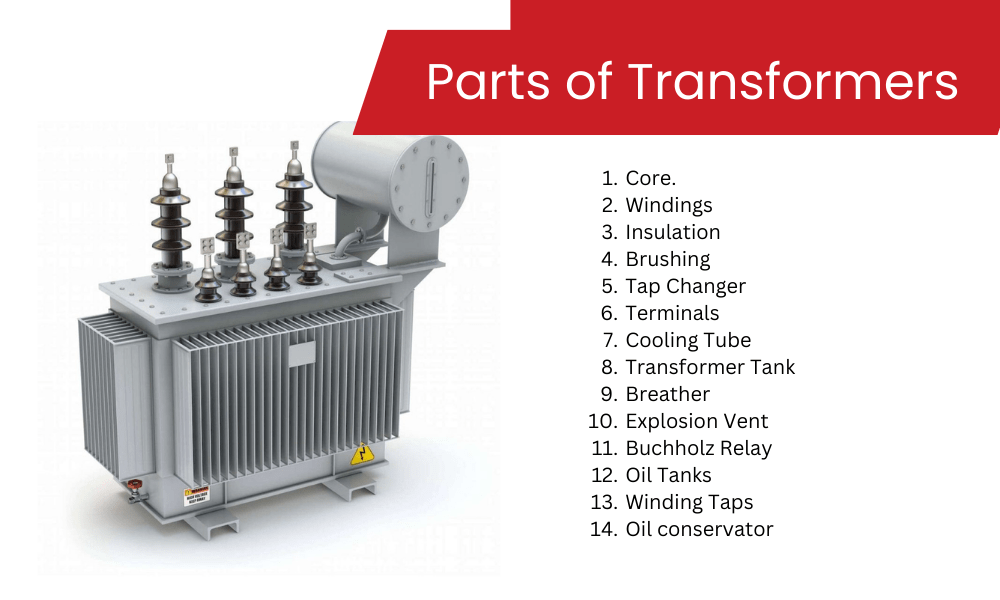

What are the 14 parts of the Transformer?

Transformers are essential electrical devices used to transfer electrical energy between two or more circuits through electromagnetic induction, consisting of several important parts, each with specific functions. Here are the different parts of a transformer and their functions:

1. Core:

The core, a basic part of a transformer, refers to the magnetic core around which the primary and secondary windings are wound. Soft iron is used to reduce eddy current loss and hysteresis loss and provide a low reluctance path for flux current.

- Function: The core of the transformer has two main functions. First, it provides a low-resistance path for the magnetic flux, ensuring efficient coupling between the windings. Secondly, it confines the magnetic field within the transformer to minimise losses and prevent interference.

2. Windings:

Another basic part of the transformer is its windings, consisting of two sets: the primary, linked to the input voltage, and the secondary, linked to the load, typically constructed using insulated copper or aluminium wire, facilitating energy transfer between high voltage and low voltage circuits.

- Function: The primary winding of the transformer receives an input voltage, inducing a changing magnetic field, and the secondary winding produces a voltage based on the turns’ ratio, enabling efficient voltage transformation for electricity distribution by stepping up or stepping down voltage levels as needed for transmission and utilisation purposes.

3. Insulation:

Transformer insulation refers to the utilisation of specific materials or methods to hinder or diminish the transfer of heat, electricity, or sound between elements or within systems.

- Function: Insulation is essential for safe and efficient equipment operation, providing electrical, thermal, and mechanical insulation. It is placed between windings, turns, and all current-carrying parts and the tank to prevent electrical hazards, maintain temperature stability, and ensure mechanical durability, thus enhancing equipment longevity and reliability.

4. Bushings:

Transformer bushings are electrical devices used in power transformers and other electrical equipment to provide insulation and support for the conductors that pass through the walls of the equipment.

- Function: A vital role that bushings play is to act as a barrier between the terminals and the tank, ensuring electrical insulation and preventing current or oil leakage. They also securely connect internal electrical components to external circuits, ensuring safe and efficient electricity flow while maintaining insulation and containment integrity.

5. Tap Changer:

An important part of a transformer, the tap changer enables the adjustment of the transformer’s turns and voltage ratios by shifting the tapping point on the winding. There are two types of tap changers: on-load, which allows changes without isolating the transformer from the supply and off-load, which requires disconnecting the transformer from the supply

- Function: The core purpose of a tap changer is to control the transformer’s output voltage, compensating for input voltage fluctuations or changes in load conditions. By manipulating the tapping point on the winding, the tap changer modifies the turn ratio, thereby adjusting the output voltage.

6. Terminals:

Transformer terminals are essential connection points in transformers, with primary terminals receiving high-voltage electrical energy and secondary terminals delivering lower voltage to loads.

- Function: The primary function of transformer terminals is to facilitate the safe and efficient transfer of electrical energy to and from the transformer. They enable the connection of power lines, secondary circuits and other components, ensuring the seamless flow of electricity for various applications.

7. Cooling Tube:

Cooling tubes, also known as cooling pipes or cooling channels, are channels or conduits integrated into the design of transformers, used to cool the transformer by facilitating the circulation of a coolant, typically oil or a cooling medium, for efficient heat dissipation.

- Function: The primary function of cooling tubes in transformers is to remove heat generated during transformer operation, cool the transformer oil, and maintain the transformer’s operating temperature within acceptable limits. They enhance the cooling process by providing a pathway for the circulation of coolant in proximity to the core and windings.

8. Transformer Tank:

The transformer tank is a sealed enclosure or container that houses the essential components of a power transformer, including the core, windings, insulation, cooling systems, and various auxiliary devices.

- Function: The primary function of the transformer body or tank is to provide a protective and secure housing for the internal components of the transformer. It contains the core and windings, ensuring their mechanical stability and protecting the transformer from external damage or contamination.

9. Breather:

A breather, also known as a silica gel breather or air breather, is a device used in power transformers to control the quality of air entering and leaving the transformer shell.

- Function: The primary function of a breather is to prevent moisture and dust from entering the transformer. It helps maintain the integrity and insulation properties of the transformer oil by ensuring that the air inside the tank remains dry and free from contaminants.

10. Explosion Vent:

An explosion vent, a metallic pipe positioned just above the conservator tank and featuring a diaphragm at one end, is a specific type of pressure relief device used in transformers to mitigate the risks associated with explosions or rapid pressure buildup.

- Function: The primary purpose of an explosion vent is to safely release pressure and gases during an explosion or pressure surge, diverting forces away from vital transformer parts to prevent extensive damage and catastrophic failure.

11. Oil Tank:

An oil tank refers to the container or enclosure that houses the transformer oil, such as mineral oil and silicone oil. These tanks are typically constructed from robust materials like steel to provide both structural integrity and the ability to endure the mechanical and thermal challenges that come with the operation of transformers.

- Function: The primary purpose of the oil tank is to store and contain the transformer oil. It holds a sufficient quantity of oil to ensure proper cooling and insulation of the transformer during operation. The oil tank is designed to withstand the pressure changes and expansion of the oil due to temperature variations.

12. Buchholz Relay:

The Buchholz relay, one of the most important components of oil-immersed transformers rated over 500kVA, is a protective device used to detect faults and abnormal conditions within the transformer.

- Function: The primary function of the Buchholz relay is to detect faults occurring in the parts immersed in the oil of the transformer, such as internal short circuits or the accumulation of gases. It serves as an early warning system to prevent further damage or failure by operating on the gases emitted by breaking down transformer oil during internal faults.

13. Winding Taps:

Winding taps are additional connection points on the transformer windings that provide flexibility in adjusting the turn ratio of the transformer.

- Function: The main function of winding taps is to allow for voltage regulation and adjustment to match specific load requirements or compensate for varying input voltages. By changing the connection point on the windings, the turns ratio can be modified, resulting in a corresponding change in the output voltage of the transformer.

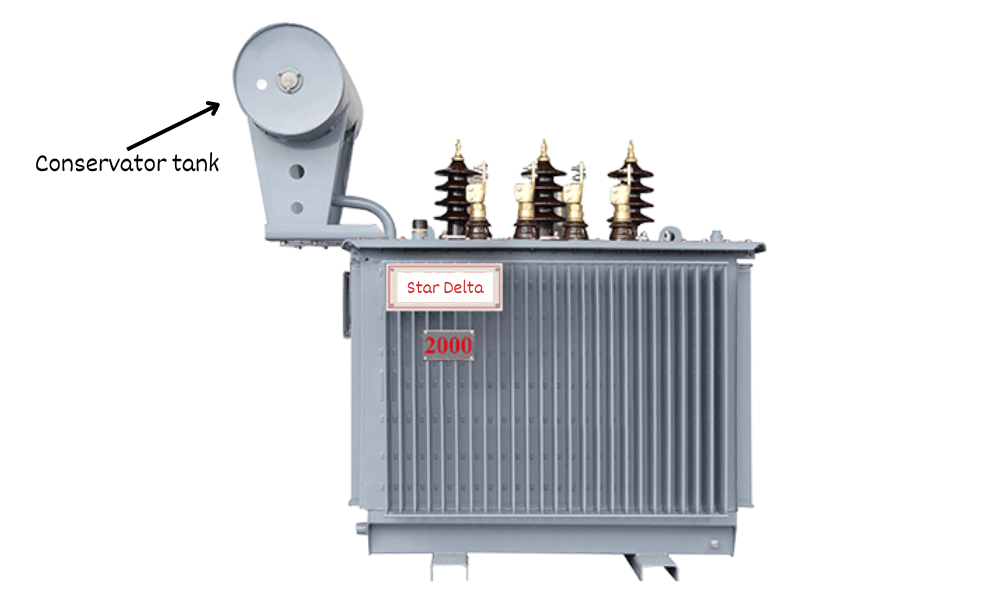

14. Oil conservator:

The conservator is an expansion tank connected to the transformer’s oil tank, accommodating oil volume changes due to temperature variations.

- Function: The oil conservator’s main role is to ensure a stable oil level within the transformer. It achieves this by accommodating oil volume changes resulting from temperature fluctuations. Connected to the main tank via a pipe, the oil conservator tank effectively compensates for oil expansion and contraction, thereby maintaining the oil level within the desired operating range.

Comparison of Components: Single-Phase vs. Three-Phase Transformers

Single-phase and three-phase transformers share many common components, but they also have some differences in their design and construction due to their distinct operating principles. Here’s a comparison of the parts in single-phase and three-phase transformers:

Common Components:

- Core: Both single-phase and three-phase transformers’ core is made of laminated iron or steel sheets, providing a low reluctance path for magnetic flux and enhancing the transformer’s efficiency.

- Primary and Secondary Windings: Both transformer types feature primary and secondary windings made of insulated copper or aluminium wire to facilitate energy transfer from the input to the output circuit.

- Insulation: Insulation materials are used in both transformers to electrically isolate the windings from each other and from the core, preventing electrical arcing and ensuring safe operation.

- Cooling System: Transformers generate heat during operation, and both types require cooling systems mounted on the transformer tank to dissipate this heat and maintain safe operating temperatures.

- Conservator: Many single-phase and three-phase transformers have conservator tanks, which are expansion tanks connected to the oil-filled transformers.

- Oil Tank: Oil tanks are present in both transformers to serve as a cooling and insulation medium, enhancing overall transformer performance and safety.

Differences in Components:

- Windings Arrangement: Single-phase transformers have two windings—one primary and one secondary—while three-phase transformers have three primary and three secondary windings. The arrangement of these windings differs significantly due to the distinct requirements of single-phase and three-phase systems.

- Core Design: Three-phase transformers often have a more complex core design to accommodate the multiple windings and phases. This design may include a three-legged or five-legged core, depending on the configuration.

- Size and Weight: Three-phase transformers are typically larger and heavier than single-phase transformers because they handle a higher power capacity, and their windings and the core structures are more extensive.

- Winding Taps: Single-phase transformers may have multiple winding taps for voltage adjustments, whereas three-phase transformers may have additional taps to account for the varying voltage requirements of different loads and phases in a three-phase system.

Summing Up!

A transformer is a masterpiece of engineering where each component plays a crucial role in the seamless transformation of electrical energy. Every element of a transformer, from the magnetic cores guiding the essence of power to the intricate windings transporting currents of change, harmoniously combines to allow precise voltage adjustments, ensuring the uninterrupted flow of electricity across the grid.

Star Delta acknowledges the critical role that transformers play in contemporary electrical systems, and it is our commitment to offer an extensive array of services and products tailored to fulfil your transformer requirements. Whether your needs pertain to transformer installation, maintenance, repairs, or expert consultation, our team of proficient specialists is at your service.

Our services encompass the entire lifecycle of transformers, from design and engineering to testing and commissioning. Contact us today to fully leverage our advanced products and customer-centric solutions.