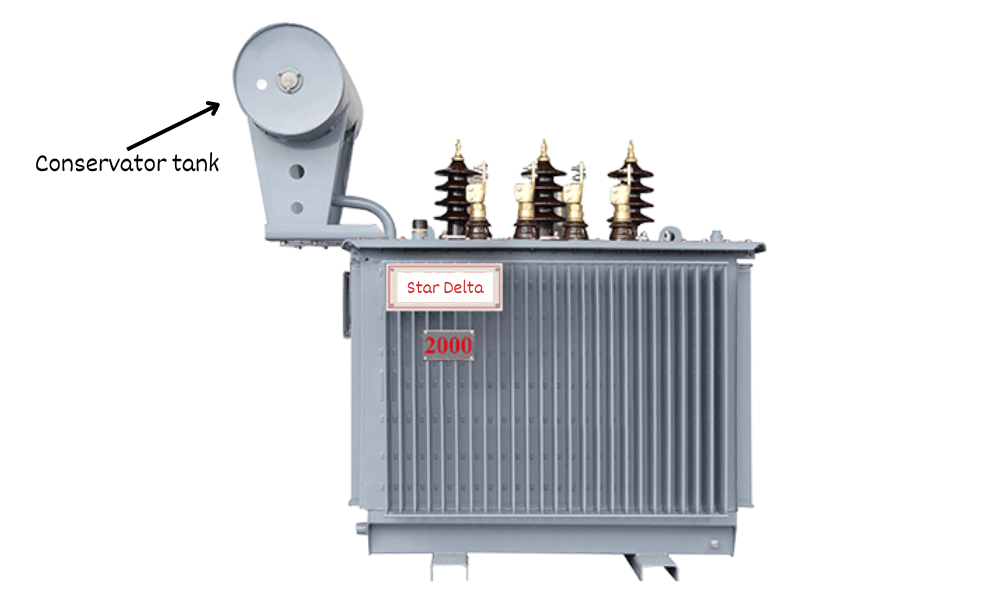

A conservator tank of a power transformer is a cylindrical container that stores insulating oil. It serves to regulate the oil level, allowing for the expansion and contraction of oil due to temperature changes while maintaining proper insulation in the transformer.

Have a unique project? Always Contact Star Delta for specialised conservator tanks and transformers that are designed to meet your specific needs. Boost your energy efficiency with our reliable and efficient autotransformers.

What is a Conservator Tank?

The conservator main tank is a critical part of a transformer that should not be overlooked. Its ability to regulate oil levels, manage temperature changes, and preserve oil quality is essential for the transformer’s performance and longevity. The conservator tank is not just a container; it’s a guardian of transformer health, ensuring that these vital electrical devices continue to function at their best.

As a matter of fact, a conservator tank can help extend the lifespan of a transformer by up to 30% due to its role in maintaining oil quality and regulating pressure, thereby reducing the risk of overheating and other issues. According to industry standards, the recommended level of oil in the conservator tank should be maintained at about 25-30% above the core and coil assembly to allow for thermal expansion and contraction, ensuring optimal transformer performance.

Benefits of a Conservator Tank

Understanding the multifaceted benefits of the tank is essential for optimising the performance and longevity of the conservator tank of the transformer. Unlock the true potential of your transformer’s efficiency and longevity as you read the benefits of a conservator tank below!

Pressure Control and Safety

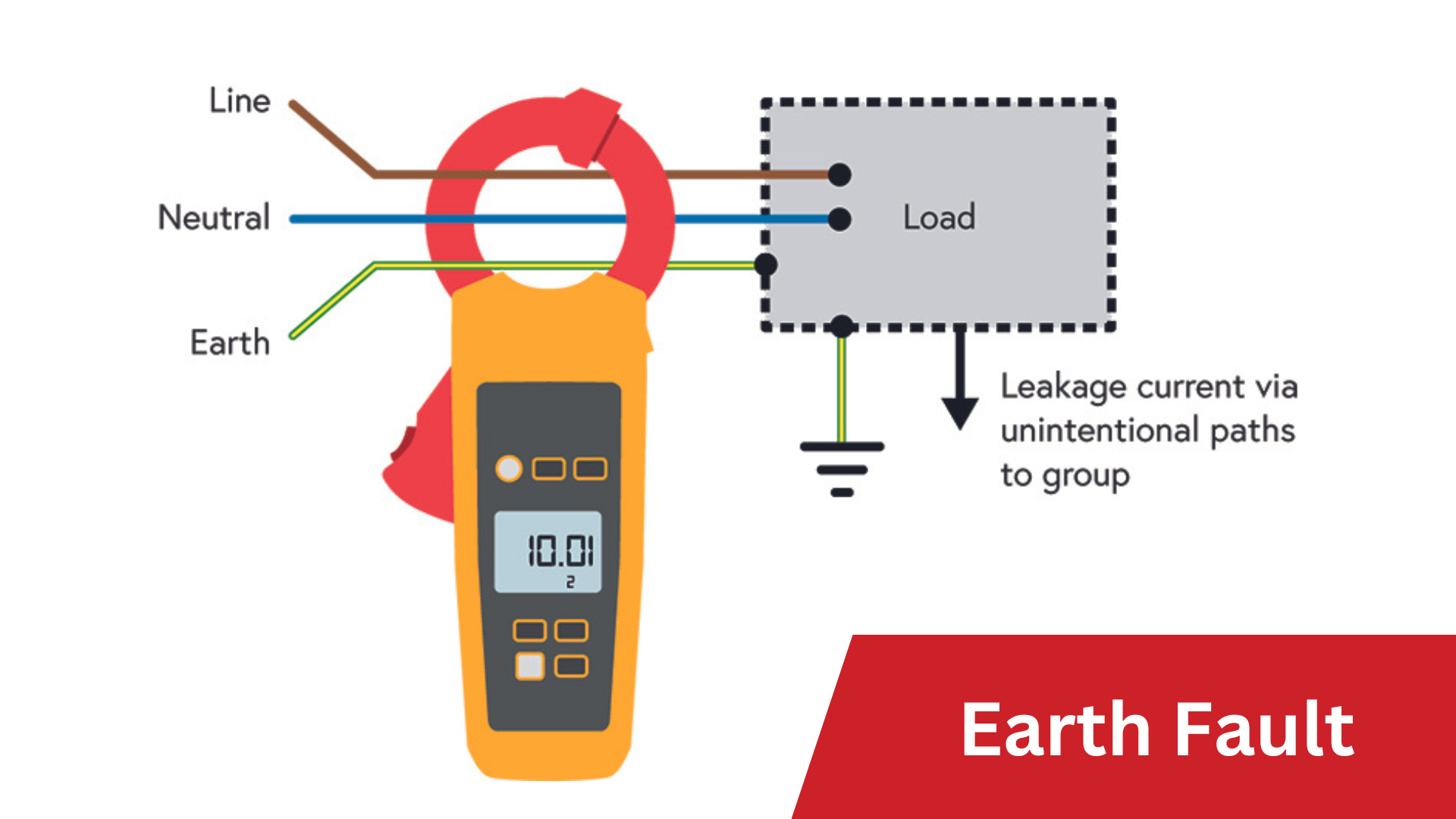

Inside the conservator, a crucial role it plays is to regulate the pressure within the transformer. As the load on the transformer varies, so does the temperature, which can lead to fluctuations in the insulating oil volume. The conservator tank acts as a safety valve in this context. Preventing over-pressurization within the main tank of the transformer ensures the structural integrity and safety of the entire system. This pressure control is not just about safeguarding the transformer but also the surrounding environment, making it an indispensable feature for transformer operation. Without this control, the risk of damage to the transformer due to excessive pressure would be significantly higher.

Preservation of Transformer Oil Quality

Maintaining the quality of the oil inside the conservator tank is a paramount concern. The controlled environment within the conservator tank ensures that the oil remains in an optimal state. It prevents moisture from infiltrating the oil, keeping it dry and uncontaminated. This preservation of transformer oil quality is essential for the insulation properties of the oil. The higher the quality, the better it can insulate, ensuring that the transformer functions efficiently and safely, especially under heavy loads.

Efficiency Enhancement

Efficiency is a core objective for any transformer. One key aspect contributing to efficiency is the maintenance of the correct oil level in the conservator. With the correct oil level and quality, the transformer can dissipate heat more effectively, ensuring that it operates at its peak efficiency. The controlled oil level and quality enhance heat dissipation, making it an indispensable element in ensuring the transformer operates optimally.

Prolonged Operational Lifespan

Transformers equipped with conservator tanks tend to enjoy a longer operational lifespan. The interplay between the conservator tank and the main tank ensures that the transformer is better equipped to withstand the rigours of continuous operation. This, in turn, contributes to the extended longevity of the transformer. A longer operational lifespan not only reduces the frequency of maintenance and replacement but also provides a cost-effective solution for electricity distribution.

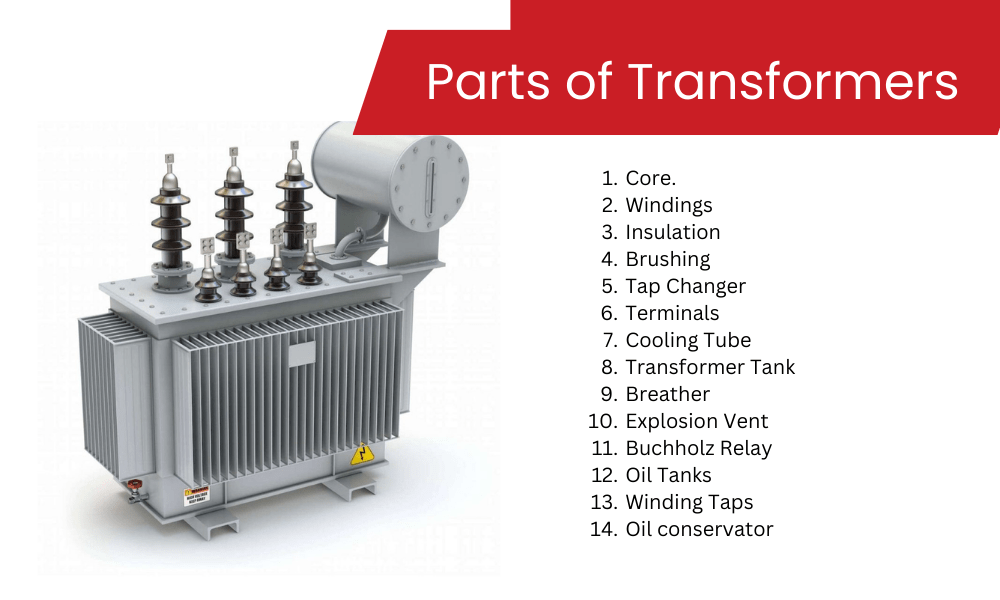

Understanding the workings of Conservator Tank

Understanding the workings of a conservator tank is crucial for comprehending its significance in the realm of transformers. Here’s how it works:

- Temperature Fluctuations: Transformers can experience temperature variations due to the electrical load they are carrying and external environmental conditions. As the temperature rises, the insulating oil in the transformer’s main tank expands, creating excess pressure.

- Expansion and Contraction: Instead of allowing the excess pressure to build up inside the main tank, the conservator tank acts as a reservoir. When the oil expands, it flows into the conservator tank, preventing over-pressurisation. Conversely, as the temperature decreases, the oil contracts and it can be drawn back into the main tank from the conservator.

- Oil Preservation: The conservator tank also helps in preserving the quality of the insulating oil. It is equipped with a breather or air vent at the top that allows air to enter and exit the tank. This breathing action minimises the contact of the insulating oil with atmospheric moisture, preventing the oil from deteriorating.

- Oil Level Indicator: To monitor the level of oil in the conservator tank, there is often an oil level indicator provided, which helps in assessing the health and condition of the transformer.

To summarise, the main function of the conservator tank of the transformer is to regulate the oil inside the transformer, ensuring that it accommodates temperature fluctuations. When temperatures rise, the conservator tank prevents over-pressurisation by acting as an air cell, allowing excess oil to flow into it, thus safeguarding the transformer. This component, the conservator tank of the transformer, plays a pivotal role in maintaining optimal operational conditions. Whether the transformer is switched on or off, the conservator tank stands as a silent guardian, efficiently managing the insulating oil to ensure the transformer’s longevity and efficiency.

What are the types of conservator tanks in a transformer?

The conservator tank, a pivotal element within a transformer, comes in various forms, each tailored to specific operational needs. Each type offers unique advantages and characteristics, ensuring that the conservator tank can effectively play its role in maintaining the transformer’s efficiency and performance. Let’s dive right in!

Standard Transformer Conservator Tank

This is the most common type of conservator tank found in transformers. It is equipped with a breather to allow air to flow in and out, enabling the expansion and contraction of the oil as temperatures fluctuate. Silica gel may be used as a desiccant to maintain the dryness of the oil inside the transformer tank. The oil level in the transformer is regulated by the movement of oil between the main tank and the conservator tank, ensuring it stays at the appropriate level.

Discover the ideal voltage transformation solutions to optimise your power distribution. Explore Our Range of Step-Up and Step-Down Transformers Today!

Buchholz Relay Conservator Tank

In addition to the standard features, this type of conservator tank is integrated with a Buchholz relay. The Buchholz relay is a protective device that detects gas or oil pressure changes within the transformer. It serves as an early warning system for potential issues, adding an extra layer of safety and protection to the transformer. The oil level in the transformer is closely monitored for any abrupt changes that could indicate problems.

Nitrogen-Sealed Conservator Tank

In this type, the conservator tank is sealed with nitrogen gas instead of allowing air to enter. Nitrogen is an inert gas that prevents the contact of oxygen and moisture with the oil inside the transformer. This configuration ensures that the oil remains in a pristine condition and significantly extends its lifespan. The oil level is maintained within the transformer by the pressure of the nitrogen gas.

Bladder-Type Conservator Tank

Bladder-type conservator tanks are designed with a flexible bladder or diaphragm inside, which separates the oil from the air. As the oil volume changes due to temperature fluctuations, the diaphragm expands and contracts accordingly. This type is particularly effective in preventing contact between the oil and air, making it ideal for situations where oil contamination must be minimised. The movement of the diaphragm regulates the oil level in the transformer.

Free-Breathing Conservator Tank

This type is similar to the standard conservator tank, but it does not incorporate a breather or desiccant like silica gel. Instead, it relies on natural ventilation to maintain the oil quality. Free-breathing conservator tanks are simpler in design and suitable for less critical applications. The oil level in the transformer is adjusted as the oil moves between the main tank and the conservator tank.

Special Transformers for Unique Applications!

Your power distribution deserves the best. Our quality power transformers are built to deliver exceptional performance, ensuring that your electricity is managed efficiently and reliably, even in demanding conditions. Whether it’s rectifiers or DC-DC converters, explore our range of DC solutions for your needs.