Have you ever wondered how electricity travels from power plants to your homes or commercial buildings? The distribution transformer is that medium that is a crucial part of the power grid, supplying reliable and safe electricity to your homes or commercial buildings.

However, you need to be aware of improved distribution transformers with emerging technologies and understand the increasing efficiency and dependability of distribution transformers. So, we are here to provide you with a complete guide and expand your knowledge on the distribution transformer.

What is Distribution Transformer?

A distribution transformer is a device linked between a high-voltage transmission line and a low-voltage distribution line that transforms electrical energy from one voltage level to another through the process of electromagnetic induction. The distribution transformer, also known as the isolation transformer, appears to be smaller in size. It has a voltage level of less than 35kv and a capacity of 6300kv and below to supply power directly to the end users.

Transformers are typically categorised according to their function, either a step-up or a step-down. The distribution transformer comes under the step-down transformer category reducing the high voltage generated from power plants to 11kv for local distribution. Step-down transformers have two high mutual inductance coil wires, and these coils share the same magnetic field despite being electrically separated. Inverters, welding equipment, voltage stabilisers, power transmission lines and other electrical distribution systems use step-down transformers.

You may also like: What is a Step-up transformer?

Types of Distribution Transformer

You might be wondering, what are the several types of distribution transformers? Well, depending on the specific requirements of the electrical distribution system, the distribution transformer comes in four types.

Single-phase:

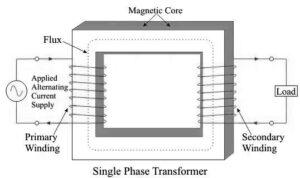

To simply understand, single-phase transformers are applicable in power applications, industrial lighting, and single-phase networks. They typically have a power rating of less than 25kVA.The single-phase consist of one pair of transformation winding such as:

- Primary winding: connected to an AC (Alternating Current) source.

- Secondary winding: attached to the load.

When the primary coil is forced to conduct an AC current, the magnetic field is produced and collapsed in the core, inducing a voltage in the secondary winding.

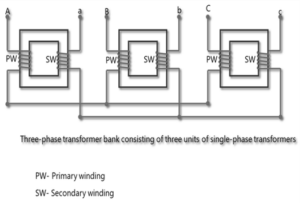

Three-Phase:

Three-Phase transformers are a combination of three single-phase transformers with the same capacity. That refers to three core legs wrapped with each two coils, which are primary and secondary. When the primary winding receives an AC voltage, the AC flows into the winding to create excitation, which creates an alternating magnetic flux in the iron core. This alternating magnetic flux also travels through the secondary winding inducing electromotive force. The power rating of three phase transformer is normally 25kVA-1000kVA. There are four types of configurations in three-phase distribution transformers named:

- Start-Star– Here, a core network connects smaller local star networks to generate a more extensive star network.

- Delta-Delta– In this, three resisters are connected in a triangle shape.

- Star-Delta– In this, three-phase electric motors are connected, with the first windings first connected in a star pattern and the running windings switched to a delta pattern.

- Delta-Star– Here, a combination of delta and star wiring connections is used to convert a three-phase electrical system to a four-wire system.

Pad-mounted:

Pad-mounted transformers are commonly used to supply power to residential and small commercial customers. They are installed in a place where there is no space for a fenced enclosure. Power ranging from 10kVA to 5000kVA, pad-mounted transformers are designed to withstand harsh environments and maximise space efficiency. This type of transformer is installed 5 meters above earthworks with electricity distribution at an overhead electrical path for dropping the primary voltage to support the customer.

Pole-mounted:

Commonly used in both urban and rural areas, pole-mounted transformers carry 11kV or 33kV voltage from the network and step it down to 240v or 415v, which is distributed to homes and businesses. They have a primary coil that steps up the voltage and a secondary coil stepping down the voltage of electrical power. Pole mounted are designed to be compact and light weighted, protected by fuses and switchgear to ensure safety and reliability.

What are the applications of distribution transformers?

If you’re curious about how distribution transformers supply your electrical equipment with a precise amount of power, consider the many uses and read more to understand its various applications.

- Stepping down Voltage: The main usage of distribution transformers is to step down electricity’s voltage from the transmission level (usually between 69 and 500 kV) to a lower voltage that is proper for use in homes and businesses.

- Power distribution: Through the distribution grid, power is distributed to users using distribution transformers. To supply electricity to homes, businesses, and other customers, they are often mounted on poles or in transformer substations.

- Voltage regulation: Distribution transformers are used for voltage regulation to avoid voltage drops over long distances. They carry out this by varying the voltage according to the demands of the load.

- Renewable energy integration: Distribution transformers are used to incorporate renewable energy sources into the electrical system. They raise the voltage of the power produced by solar cells, wind turbines, and other renewable sources so that it can be fed into the grid.

- Industrial uses: Distribution systems are also employed in industrial settings, including as manufacturing facilities, to power machinery and equipment.

Manufacturing of distribution transformers

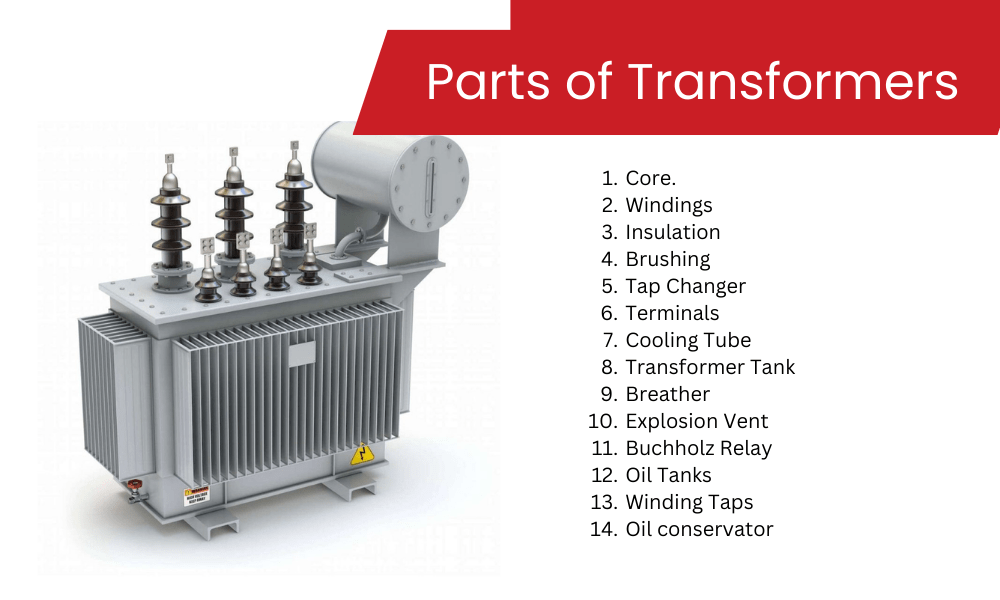

The manufacturing of a distribution transformer involves several key components that work together to transform and distribute electrical power, such as:

Core and winding material

The core is made up of laminated magnetic steel stacked together with an insulation layer in between to prevent short circuits. The core minimises magnetic flux leakage by increasing the permeability level. The shape and size of the core are figured out by the specification of voltage and current ratings. The primary winding and secondary winding, which are encircled around the core, produce a voltage. Winding is composed of copper or aluminium wire where a number of turns take place based on transformer voltage. Arrangements of winding affect the performance and efficiency of the transformer.

Cooling system:

The primary factor for generating heat in the transformer is due to the various losses like hysteresis, eddy current, and iron and copper loss. Transformer cooling systems mostly come in two types:

- Liquid cooling: To cool the transformer, liquid cooling entails pumping a liquid, such as water or oil, through the transformer. To transfer the heat to the surroundings, the liquid is often cycled through a radiator or heat exchanger.

- Air cooling: To reduce the heat generated by the transformer, air cooling is used. You can carry out this by forcing air over the transformer with fans or blowers, or you can use natural convection.

Tank:

The tank is constructed of metal sheets and equipped with oil level gauges, drain valves and pressure relief devices that play the vital role of keeping and checking the transformer. Core and winding are enclosed inside the tank after connecting to external terminals.

Looking for a reliable distribution transformer in Sydney, Australia? Don’t hesitate to reach out to Star Delta – your top-tier transformer manufacturer in NSW

What are the factors affecting transformer productivity?

To increase the performance, efficiency and life span of a transformer, you must avoid all factors, which are:

- Overloading maximises stress on the components of transforms and shortens their lifespan.

- Next, environmental factors cause damage and degrade their performance over time.

- Maintenance negligence becomes a major problem in showing its issue leading to transformer failure.

- Because transformers have a finite lifespan, this one element directly affects how well they perform is ageing.

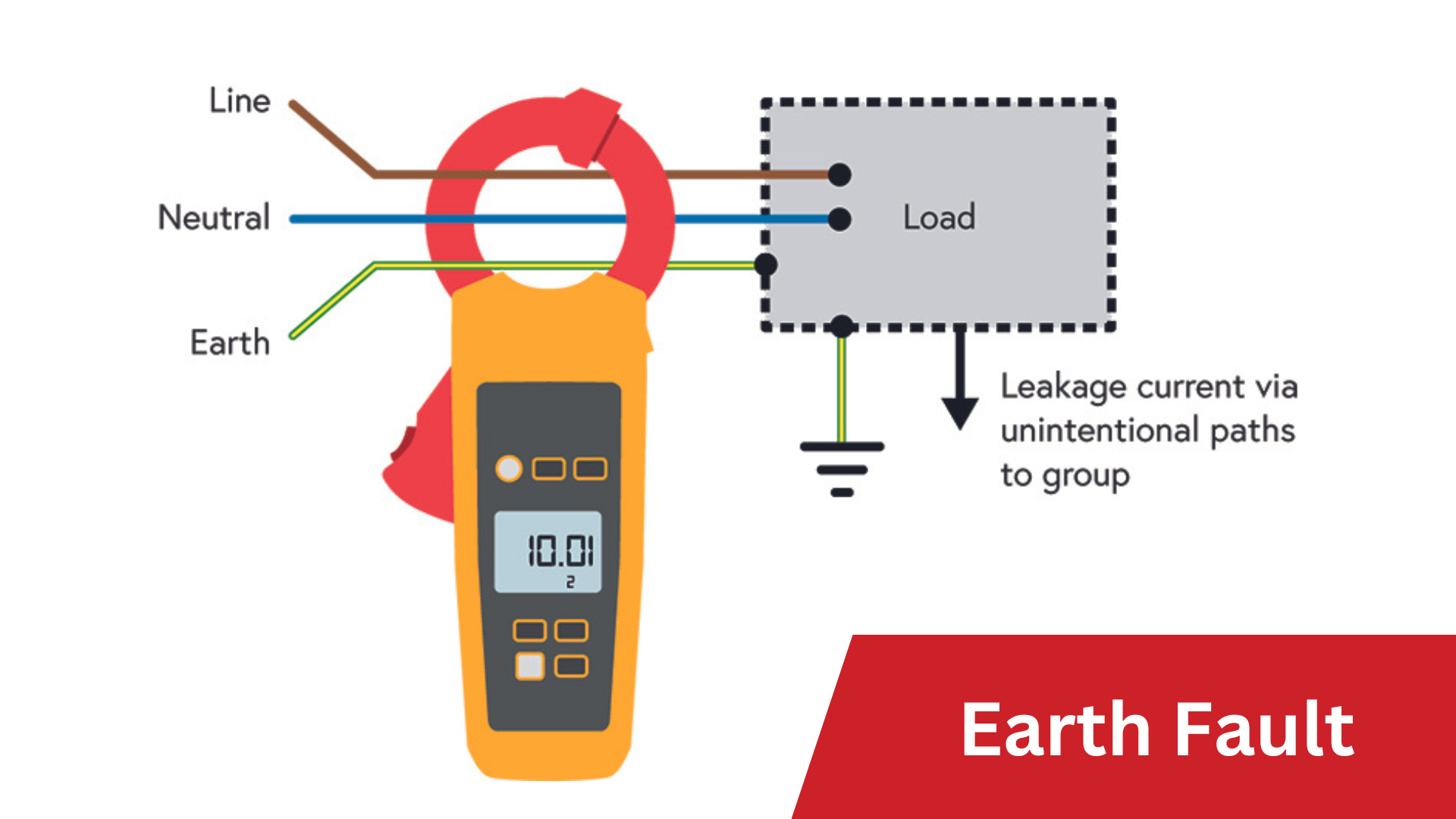

- The effectiveness of the transformer is decreased by electrical surges that damage the insulation and other components.

Proactive Measures to Prevent Transformer Damage

- Regular maintenance and inspection include oil sampling and testing of the transformer and all its components.

- Proper installation should be done under the manufacturer’s specifications or by consulting professionals.

- Install surge diverters/ circuit breakers to prevent the transformer from electrical overloads.

- Replace the transformer once its lifespan reaches the end to ensure safe and reliable operations.

- Monitor on a regular basis to detect potential issues before they become major problems.

In a nutshell, this article will provide you with a comprehensive understanding of the distribution transformer’s fundamentals. You will get a clear idea of how a transfer works and plays a vital role in our electrical system. Considering the above-mentioned will aid you in getting the desired transformer according to your need. Get in touch with us if you are looking for a reliable, high-quality distribution transformer. Contact us today for the most efficient distribution transformer available that will last a long time.