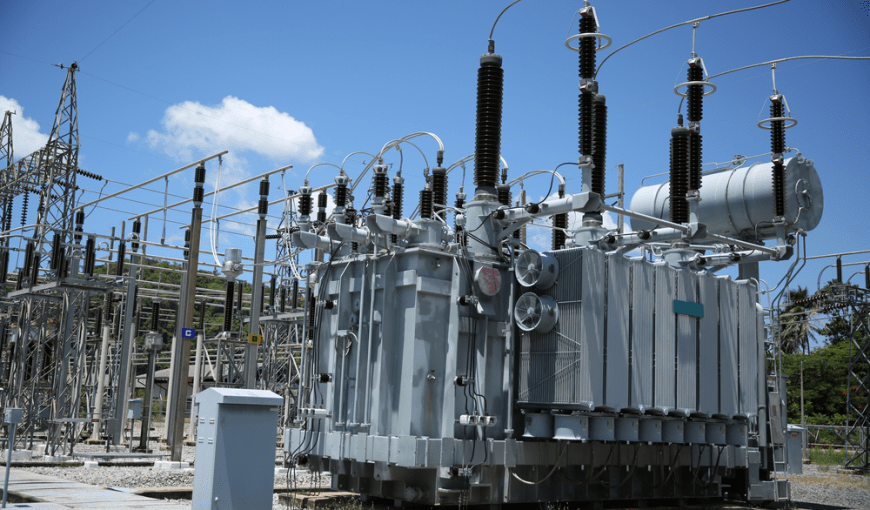

Electrical transformers, along with other discoveries of running water, gaslighting, and steam power, should be credited with the most significant developments in the industrial era. This implies that the transformer converts electrical energy from a higher level to a lower level. There are various types of transformers designed to deal with different voltage levels, such as step-down and step-up transformers.

Variations and developments in transformers occur as inventions improve on a daily basis. Because there are numerous types of transformers, this article will focus on the step-up transformer, it’s a working mechanism, benefits, and applications.

What is Transformer?

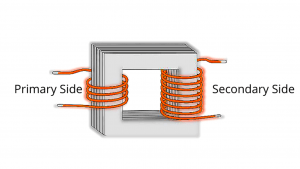

A transformer is a static, passive electrical device that galvanically transfers electrical energy between two or more circuits.

A changing current in a coil causes a changing magnetic flux in the same coil, which causes a varying emf (electromotive force) across another wounding wound on the same core.

This electrical energy is transferred magnetically between the two coils, which are not electrically connected. Transformers are rated in VA, KVA, or MVA units.

Transformers are used to increase or decrease the alternating voltage.

Depending on the primary and secondary windings, the transformers can be step-up or step-down transformers.

What is a Step-Up Transformer?

A step-up transformer transforms low voltage (LV) and high current values from the primary side of the transformer to high voltage (HV) and low current values on the secondary side. A step-down transformer is the inverse of this.

A step-up transformer uses magnetic induction to convert a high-current, low-voltage input to a low-current high-voltage output. In the primary section, the alternating electric flux produces a varying magnetic field in the core. As a result, an alternating current is produced in the secondary section. The output value will be greater than the input voltage if the number of turns in the secondary winding is greater than those in the primary section.

The other factors, such as nominal power and functional frequency levels, are remarkably similar on both sides of the windings because the transformer is very effective when the voltage and current levels are generally different.

Because this device provides galvanic isolation for electrical systems, a step-up transformer is more important and provides reliable transmission.

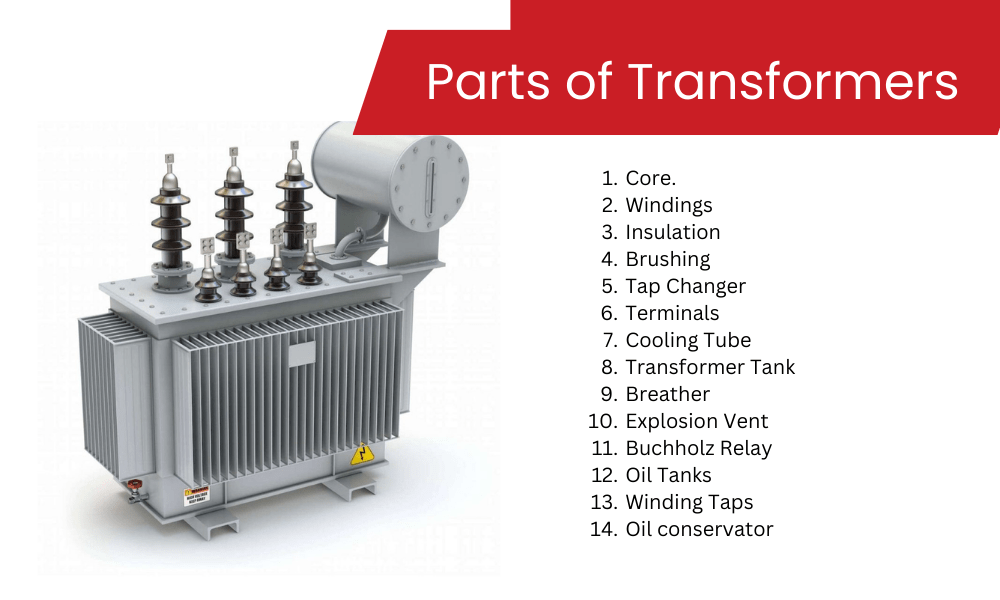

Construction of a Step-Up Transformer

The construction of a step-up transformer is so simple. It has a few essential components, such as the core and windings sections. And these sections are mentioned below:

Core

The design of the core section can be done by using a highly permeable material. By using a core substance in the device, it allows minimal wastage of magnetic current flow, such as eddy current loss due to hysteresis. The magnetic flux lines across the core substance are restricted because the permeability levels of the core are greater than that of air. Thus, ferrite substances and silicon steel are chosen for the creation of magnetic cores because they have low coactivity and hysteresis. As a result, by reducing transformer waste, the efficiency of the transformer can be increased.

The core section of the transformer can also be wounded to keep the eddy current wastage at a low value and thus reduce core heating. When the core is heated, there is less loss of electrical power, and the transformer’s efficiency may be reduced.

Windings

Step-up transformer windings help to transfer the current generated in the transformer. Windings are typically built to cool the transformer and to handle testing and functionality conditions. Despite having a higher density in the primary section, the coil has fewer turns. Similarly, the secondary section’s coil density is narrower and has more turns. Windings can be designed in such a way that the primary section holds the least amount of energy when compared to the secondary section.

The transformer’s winding material is composed of aluminium and copper. Although the cost of aluminium is not higher when compared to copper, using a copper material can extend the life of the transformer. There are various types of laminations for minimising eddy current waste, such as EI or EE type.

Precautions

- When there is a possibility of burning in the device, the power cord must be quickly removed.

- Any metallic substances should not be present near the experimental site because the device functions as a magnet and attracts magnetic devices.

- Only the experiments must be carried out under perfect supervision and experience.

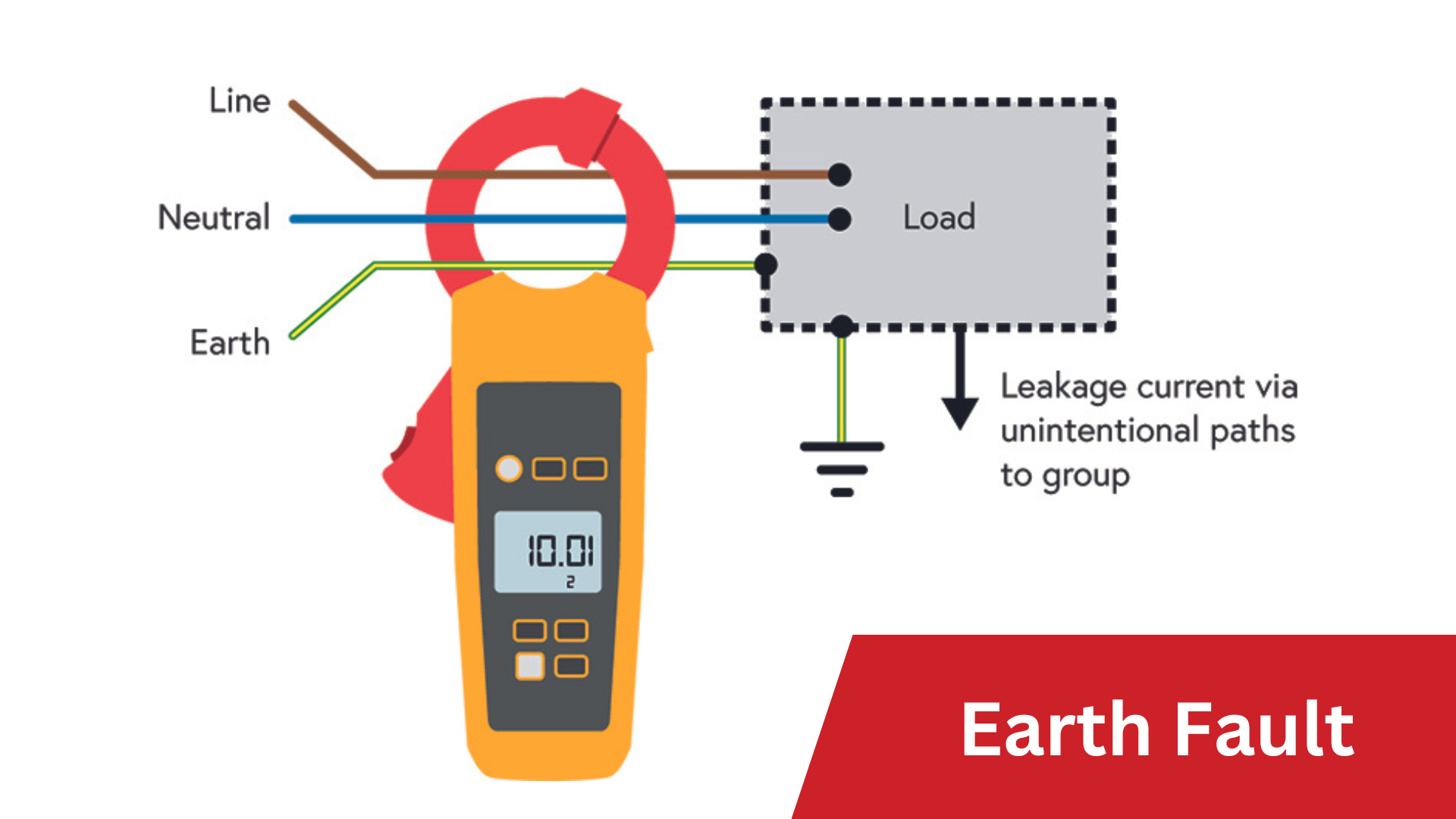

How a Step-Up Transformer Works

This section describes how a step-up transformer works. The voltages at the input and output sections of the circuit are denoted by V1 and V2, respectively, and the coil turns at the primary and secondary windings are denoted by T1 and T2. Because the coil turns are greater in the secondary winding, the output value is greater only in the secondary section. As alternating current flows through the device, the transformation of current that flows in one direction to another occurs.

The flow of current tends to generate magnetic flux in the winding area, and when the path of current flow changes, the direction of the magnetic pole changes. When the secondary winding is placed in the vicinity of moving magnetic flux, voltage is generated. As a result of the alternating current in the primary section generating a moving magnetic flux, voltage generation occurs at the secondary winding.

The primary function of a step-up transformer is generator step-up, which is a GSU component found in almost all power plants. These devices have higher turn ratios. Voltage generation during energy production can be enhanced and used for long-distance transmission applications. This generated energy has a higher current and a lower voltage value.

According to data collected from generating plants, the standard primary value of a GSU device ranges from 6 to 20 kV, while the standard secondary value ranges from 110 to 410 kV, depending on the energy transmission network connected to the GSU secondary section. The current value on the primary side is higher and can be in the range of nearly 30000 Amps based on the typical transformer power. This appears to have no potential for power broadcasting at the moment, and it must be minimised due to transmission power wastes, which are RI2. Furthermore, GSU devices create galvanic isolation between the generator and the electrical system.

Applications of Step-up Transformer

Now that we know how a step-up transformer works let’s take a look at some of its most common applications. The following are some of the most common real-world applications of step-up transformers:

1. Distribution of Electric Power

The electrical energy generated should travel many miles before reaching our home. The energy will be wasted along these lines because the conditions are not always ideal. This waste is proportional to the square of the current flowing across the lines (RI2). The power of the generated electricity is a result of low voltage and high current. The wastes that would result would make transferring electricity to any region far from the generating source impractical.

In this case, a step-up transformer can transform the low-voltage input into a low-current, high-voltage voltage output. This output will then not have such a high waste rate. As a result, transformers are an essential component of the power distribution network.

2. Electrical Appliances

Even though the voltage of the electrical power being transformed is high, it is stepped down when it is delivered to our houses. However, this is done to make it suitable for general use; there are some special devices, such as microwaves, electrical motors, X-ray machines, and so on, that require a high voltage to start.

To convert the current power source to a suitable voltage, a step-up device is used. This device is usually included as part of the appliance. However, some devices, such as X-ray machines, require an external transformer.

Other uses for step-up transformers are listed below:

- These devices are used in electronic systems, such as stabilisers and inverters, to regulate voltage from low to high levels

- They are used to distribute electricity.

- They are used to modify the high voltage produced by the alternator in the transmission network.

- These transformers are also used to power an electric motor, ovens, and other appliances.

- They are used to improve electronic devices.

- In electronic devices that require voltage boosting, a small step-up device can be used. However, because of their lighter weight and smaller size, power electronic networks are increasingly being used in modern electronic instruments.

- For the efficient transmission of electrical energy, a giant power step-up device, also known as a GSU transformer, is used to step up the produced energy to a higher voltage value.

3. For the Equipment made in another Country

If we purchase an electrical instrument from another country, it will be built in accordance with the characteristics of that country. For instance, in Canada, the power source limitation is a 120V, 60Hz source. However, this is not a universal figure. Some regions have their own set of restrictions. If we bought an electrical device from a region where the main voltage is higher than 120V, we will need to use a step-up transformer to change the voltage to the desired rate for the appliance.

Choosing the Most Effective Transformer

A step-up device is an essential component of our lives, as evidenced by its applications. Sometimes its application is obvious, such as in power distribution lines, and other times it is not. However, whether we like it or not, it is responsible for the smooth operation of all electrical instruments.

As a result, we must obtain the step-up transformer from a reputable builder with a proven track record. If you want to get the best step-up transformer, you should definitely consider getting it from such builders.

Summary

In conclusion, this is all about the step-up transformer. The performance of the step-up form is to increase the voltage while decreasing the current strength. This type has a large number of coils across the second section when compared to the primary side. As a result, the wire in the primary winding is stronger than the wire in the secondary winding. Because they transport energy to remote locations, these devices are critical in transmission and power generation networks.

Contact us to learn more about Step-up Transformers

Star Delta Transformers is a leading manufacturer of step-up transformers in New South Wales. A step-up transformer raises the voltage by “stepping up” from the primary coil to the secondary coil. This can be applied to any customer requirement or application.

Call us today to know more about the transformers, we can match your needs!